Silicon Dioxide Coated Aluminum Powder: Technology, Benefits & Market Insights

2025 / 11 / 20Silicon Dioxide Coated Aluminum Powder is becoming a breakthrough material in the aluminum pigment and metal powder industry. It offers enhanced safety, oxidation resistance, and compatibility, making it widely applicable in coatings, additives, inks, and electronic products. As a leading manufacturer, Zhangqiu Metal Pigment Co., Ltd. will provide an in-depth analysis of its principles and industry value.

Silicon Dioxide Coated Aluminum Powder: Core Technology Explained

Silicon Dioxide Coated Aluminum Powder is produced by coating aluminum particles with a thin, uniform SiO₂ shell.

This structure significantly improves oxidation stability, moisture resistance, and dispersion behavior.

The product is also increasingly important as aluminum pigment powder demand grows and aluminium metal powder price fluctuates globally.

Key benefits:

-

Strong anti-oxidation ability

-

High chemical stability

-

Improved safety for storage and transport

-

Better compatibility with water-based and solvent systems

Properties & Structure of Silicon Dioxide Coated Aluminum Powder

The SiO₂ coating modifies the surface of the aluminum core through chemical or sol-gel processes.

Typical characteristics:

-

Higher ignition temperature

-

Lower gas generation

-

Greater resistance to acid/alkali environments

These features make it ideal for safer industrial-grade applications.

Manufacturing Process Overview

Although details vary by manufacturer, the typical process includes:

-

Surface Activation – Clean and activate aluminum particles.

-

Silicon Dioxide Deposition – Form a nano-level SiO₂ coating.

-

Curing & Stabilization – Improve bonding strength and resistance.

ZHANGQIU METALLIC PIGMENT uses advanced closed-loop production and quality control to ensure consistency and performance.

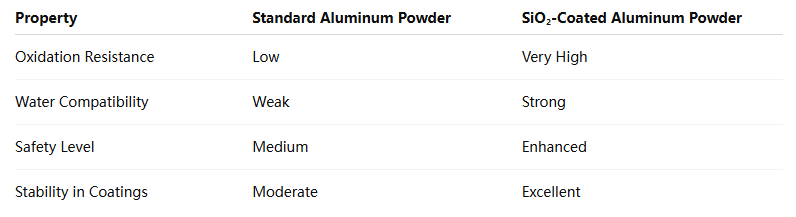

Performance Comparison with Standard Aluminum Powder

Compared with traditional aluminum pigment powder, silica-coated aluminum powder has the following characteristics:

Applications & Industry Case Comparisons

Silicon Dioxide Coated Aluminum Powder is widely used in:

-

Water-based coatings and inks

-

3C electronics coatings

-

Chemical additives & masterbatches

-

Automotive OEM coatings

-

High-precision metal pigment applications

Case Example:

A European coatings manufacturer required high-stability metallic effects for a water-borne automotive line.A European paint manufacturer needed a high-stability metallic effect coating for its water-based automotive coatings line.

Zhangqiu Metallic Pigment supplied silica-coated aluminum powder, which provides enhanced water resistance and reduces gas generation by over 60% compared to standard aluminum powder.

This improves the coating's shelf life, safety, and final gloss.

This improved shelf life, safety, and final gloss performance.

FAQ: Common Questions About Silicon Dioxide Coated Aluminum Powder

1. Is Silicon Dioxide Coated Aluminum Powder more expensive?

It can be slightly higher due to advanced surface treatment, but the improved performance offsets cost—especially when aluminium metal powder price rises globally.

2. Can it replace flake aluminum powder in all applications?

Not always. Flake aluminium powder is still essential for high-brightness metallic effects.

SiO₂-coated types are preferred when safety and stability are critical.

3. How does it compare to Leafing Aluminum Powder?

Leafing Aluminum Powder forms a floating metallic layer on surfaces, while SiO₂-coated types focus on stability and compatibility.

4. Is it safe for water-based coatings?

Yes—its enhanced oxidation resistance makes it ideal for water-based and low-VOC systems.

Conclusion & Call to Action

Silicon Dioxide Coated Aluminum Powder represents the next generation of safe, stable, and high-performance aluminum pigments. With rising market demand and increasing environmental requirements, choosing a reliable supplier is crucial.

ZHANGQIU METALLIC PIGMENT CO., LTD provides:

-

Stable supply chain

-

Customized particle size & coating thickness

-

Competitive wholesale pricing

-

ISO-certified production

Contact our technical team for samples, pricing, or customization:

Website: https://zqmetallic.com/

Email: info@zqmetallic.com

We help global manufacturers achieve safer, more efficient, and more brilliant metallic effects.