Aluminium Paste for Automotive Coatings: Enhancing Durability and Aesthetic Appeal

2026 / 01 / 17Metallic Finishes Drive Automotive Coating Innovation

Metallic finishes have become a defining feature of modern automotive design.

From premium passenger vehicles to commercial fleets, metallic coatings are widely used to convey quality, durability, and advanced engineering.

At the center of these finishes lies aluminium paste, a metallic pigment system that enables controlled light reflection, uniform appearance, and long-term performance in automotive coatings. As coating systems evolve to meet higher durability, sustainability, and visual standards, aluminium paste continues to play a critical technical role.

Why Automotive Coatings Demand Metallic Pigments

Automotive coatings face far more demanding conditions than decorative paints. They must deliver consistent appearance while protecting vehicle surfaces against harsh environments.

Key performance requirements include:

-

High and stable metallic appearance

-

Resistance to UV radiation and weathering

-

Protection against corrosion and moisture

-

Compatibility with multi-layer coating systems

Aluminium paste meets these requirements by combining visual effects with functional protection, making it one of the most widely used metallic pigments in the automotive coatings industry.

How Aluminium Paste Creates Metallic Appearance in Auto Coatings

Flake Orientation and Light Reflection

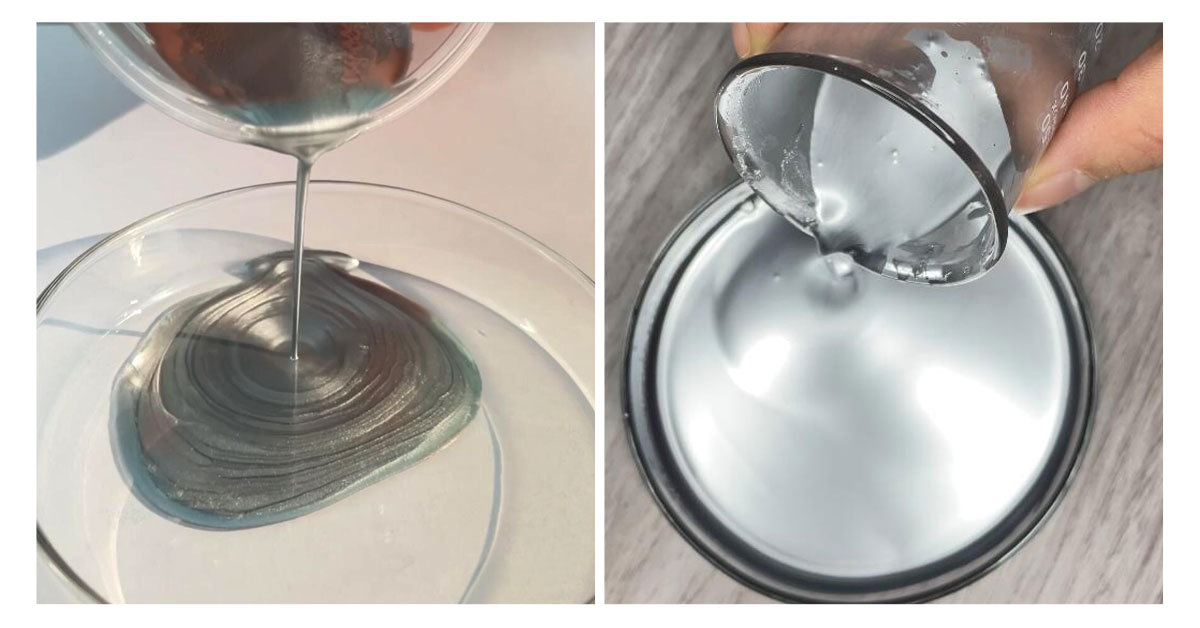

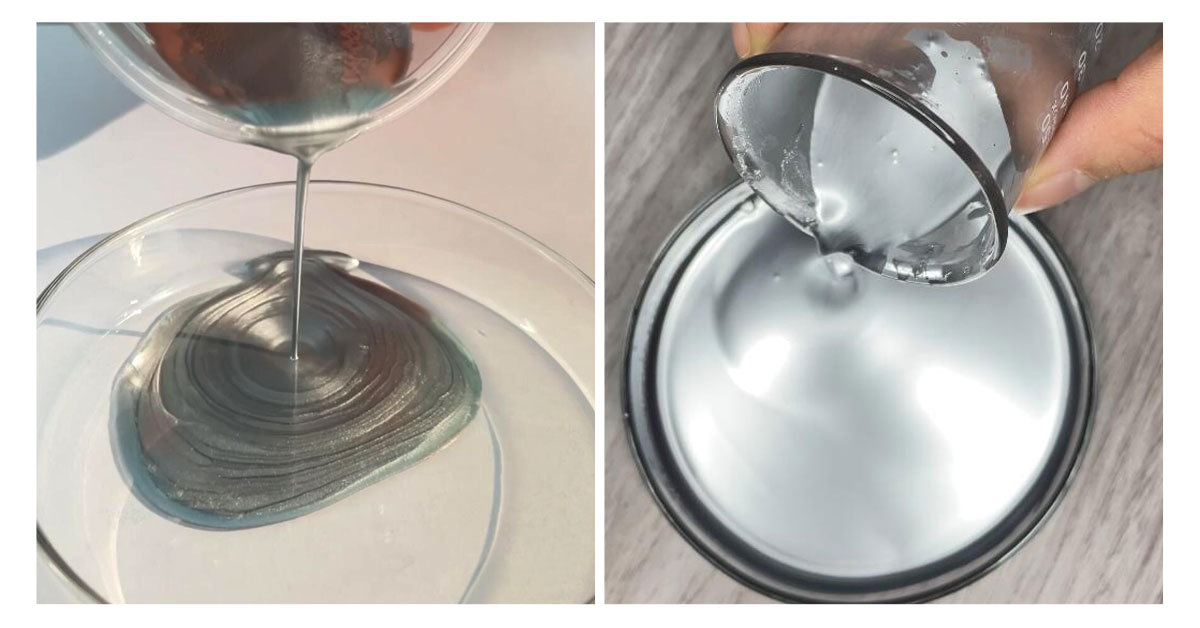

Aluminium paste consists of thin, platelet-shaped aluminium flakes dispersed in a carrier medium.

During coating application and curing, these flakes align parallel to the surface, creating a smooth, reflective layer.

This orientation enables:

-

Strong specular reflection

-

Uniform metallic brightness

-

Controlled sparkle and gloss

Compared with aluminium powder, aluminium paste offers better flake alignment and visual consistency, which is essential for large automotive body panels.

Optical Uniformity Across Vehicle Surfaces

Automotive coatings must maintain uniform color and brightness across complex shapes such as doors, hoods, and bumpers.

Properly engineered aluminium paste supports:

-

Even flake distribution

-

Reduced clouding or mottling

-

Stable appearance under different lighting conditions

This consistency is especially critical for mass production, where color deviation between panels is unacceptable.

Durability Benefits of Aluminium Paste in Automotive Applications

Barrier Protection and Corrosion Resistance

Beyond aesthetics, aluminium paste contributes to coating durability through a flake-based barrier effect.

When aluminium flakes overlap within the coating film, they form a layered structure that:

-

Slows moisture penetration

-

Reduces oxygen diffusion

-

Enhances corrosion resistance of metal substrates

This “fish-scale” barrier mechanism is particularly valuable in automotive primers and intermediate layers.

Resistance to Weathering and UV Exposure

Automotive coatings are continuously exposed to sunlight, temperature fluctuations, and environmental pollutants.

High-quality aluminium paste demonstrates:

-

Excellent resistance to UV degradation

-

Minimal loss of metallic brightness over time

-

Stable appearance after prolonged outdoor exposure

These properties help vehicles retain their visual appeal throughout their service life.

Aluminium Paste vs Aluminium Powder in Automotive Coatings

While both aluminium paste and aluminium powder are used in coatings, their performance differs significantly in automotive systems.

| Property | Aluminium Paste | Aluminium Powder |

|---|---|---|

| Flake shape | Platelet | Irregular / granular |

| Metallic appearance | Smooth, uniform | Less consistent |

| Dispersibility | High | Moderate |

| Orientation control | Excellent | Limited |

| Automotive suitability | High | Limited |

Due to its superior dispersion and orientation control, aluminium paste is generally preferred for automotive coatings where appearance and durability are critical.

Compatibility with Modern Automotive Coating Systems

Solvent-Based and Waterborne Systems

Advances in aluminium paste technology have expanded compatibility with both traditional solvent-based and newer waterborne automotive coatings.

Modern formulations address challenges such as:

-

Oxidation control

-

Stability in aqueous environments

-

Interaction with resins and additives

As a result, aluminium paste can now be used across a wide range of automotive coating systems without compromising performance.

Multi-Layer Coating Structures

Automotive coatings typically consist of multiple layers, including primers, basecoats, and clearcoats.

Aluminium paste is most commonly used in basecoats, where it provides metallic appearance while remaining compatible with clearcoat layers that protect against abrasion and UV exposure.

Quality Control and Processing Considerations

To achieve consistent results in automotive coatings, several factors must be carefully controlled:

-

Aluminium flake size and thickness

-

Paste concentration and dispersion quality

-

Mixing speed and shear conditions

-

Application method and film thickness

Proper control of these parameters ensures stable appearance and repeatable performance in large-scale automotive production.

Market Trends Driving Aluminium Paste Use in Automotive Coatings

Several global trends continue to support the use of aluminium paste in automotive applications:

-

Growing demand for premium metallic finishes

-

Increased vehicle production in emerging markets

-

Stricter durability and corrosion resistance standards

-

Shift toward lightweight materials requiring advanced coatings

According to industry analyses, metallic pigments remain a core segment of the automotive coatings market, with aluminium paste maintaining a dominant position due to its balance of performance and cost efficiency.

Sustainability and Future Development

Although durability and appearance remain primary drivers, sustainability is increasingly shaping automotive coating technologies.

Ongoing developments in aluminium paste focus on:

-

Improved compatibility with low-VOC systems

-

Reduced odor formulations

-

Enhanced efficiency through optimized flake geometry

These advancements allow aluminium paste to support both aesthetic and environmental goals in modern automotive manufacturing.

Conclusion

Aluminium paste plays a vital role in automotive coatings by delivering both metallic appearance and long-term durability. Through controlled flake orientation, barrier protection, and compatibility with advanced coating systems, it meets the demanding requirements of the automotive industry.

As vehicle design trends continue to emphasize visual quality, performance, and sustainability, aluminium paste is expected to remain a key component in automotive coatings, supporting innovation across global markets.